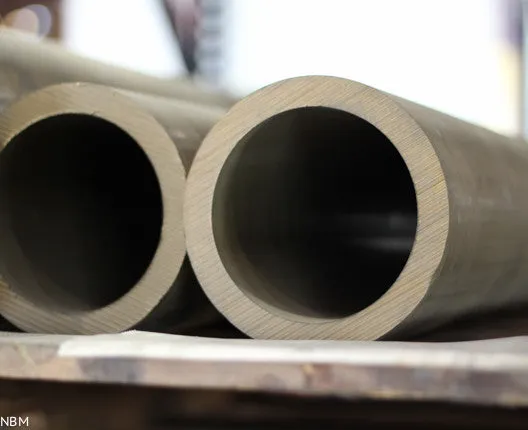

Typical Uses for C92700 Leaded Tin Bronze:

FASTENERS: Lead Screw Nuts

INDUSTRIAL: Pump Pistons, Steam Fittings, Bushings, Gears, Pump Impellers, Heavy Duty Bearings, Bearings

| Al | Sb | Cu | Fe | Pb | Ni | P | Si | S | Sn | Zn | |

| Min/Max | 0.005 | 0.25 | 86.0 - 89.0 | 0.2 | 1.0 - 2.5 | 1 | 0.25 | 0.005 | 0.05 | 9.0 - 11.0 | 0.7 |

| Nominals | - | - | 87.5000 | - | 1.8000 | - | - | - | - | 10.0000 | - |

| Product Type | Temper Type |

| Continuous | ASTM B505, B505, SAE J461, J462 |

| Ingot | ASTM B30, B30 |

| Sand | SAE J462, J461 |

| Temper | Sect. Size | Cold Work | Type Min | Temp | Tensile Strength | YS 0.05% UL | YS 0.02% Offset | YS 0.005% Offset | Elong. | RH B | RH C | RH F | RH 30T | VH 500 | BH 500 | BH 3000 | Shear Strgth | Fatigue Strgth | Izod Impact Strgth |

| - | in. | % | - | F | ksi | ksi | ksi | ksi | % | B | C | F | 30T | 500 | 500 | 3000 | ksi | ksi | ft-lb |

| - | mm. | - | - | C | MPa | MPa | MPa | MPa | - | - | - | - | - | - | - | - | MPa | MPa | J |

| As Continous Cast | |||||||||||||||||||

| M07 | 68 | 38 | 20 | - | - | - | - | - | - | - | - | - | - | - | - | ||||

| M07 | 0 | SMIN | 20 | 262 | 138 | - | - | 8 | - | - | - | - | - | - | - | - | - | 0 | |

| As Sand Cast | |||||||||||||||||||

| M01 | 68 | 42 | 21 | - | - | - | - | - | - | - | - | - | - | - | - | 7 | |||

| M01 | 0 | TYP | 20 | 290 | 145 | - | - | 20 | - | - | 78 | - | - | 77 | - | - | - | 9 |

| Product Property | US Customary | Metric |

| Coefficient of Thermal Expansion | 10.0 . 10-6 per oF (68-392 F) | 18.0 . 10-6 per oC (20-200 C) |

| Density | 0.317 lb/in3 at 68 F | 8.78 gm/cm3 @ 20 C |

| Electrical Conductivity | 11 %IACS @ 68 F | 0.064 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 94.0 ohms-cmil/ft @ 68 F | 15.63 microhm-cm @ 20 C |

| Incipient Melting | 600 oF | 315 C |

| Melting Point - Liquidus | 1800 F | 982 C |

| Melting Point - Solidus | 1550 F | 843 C |

| Modulas of Elasticity in Tension | 16000 ksi | 110000 MPa |

| Specific Gravity | 8.78 | 8.78 |

| Specific Heat Capacity | 0.09 Btu/lb/oF at 68 F | 377.1 J/kg . oK at 293 K |

| Thermal Conductivity | 27.2 Btu . ft/(hr . ft2 . oF)at 68F | 47.0 W/m . oK at 20 C |

| Joining Technique | Suitability |

| Brazing | Good |

| Coated Metal Arc Welding | Not Recommended |

| Gas Shielded Arc Welding | Not Recommended |

| Machinability Rating | 45 |

| Oxyacetylene Welding | Not Recommended |

| Soldering | Excellent |

| End Product | Specification |

| Continuous | ASTM B505, B505, SAE J461, J462 |

| Ingot | ASTM B30, B30 |

| Sand | SAE J462, J461 |